Product examples

Optics/POF

Since 2007 we have developed manufacturing know-how for optical plastic parts. This enables us to be your competent partner during the entire process chain from the design of optical components to series production in injection-moulding.

Our competencies in optical injection-moulding:

- Design of new optical components, simulation of the light beams with partners

- Mould-fill simulations using finite element method (FEM) for an optimal filling

- Design of the tools

- Production of the tools in our own tool shop. This includes the high-precision machining of mould inserts in order to be able to meet the requirements in the optical sector (diamond machining is also possible with our competent partners).

- Injection-moulding using modern and all-electric machines

Current examples of topics:

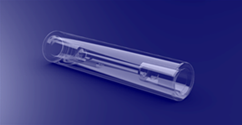

LED optical head for bicycle headlight

Light-controlling LED optical head for the visualisation of complex projection of the light beam, enabling approval in accordance with German road traffic licensing regulations (StVZO) in the overall system.

Competencies brought by FWB:

- Calculation of optical beam paths (still done externally)

- Concept and construction of the tool

- Mould-fill simulations for optimal process conditions in the tool shop

- Production of components in injection-moulding: streak-free and stress-free quality without flow lines. We meet the dimensional requirements and highest quality demands.

- 3D measurement of sink marks

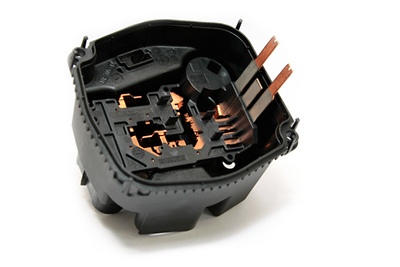

POF (Polymer optical fibres)

Polymer optical fibres are primarily used in digital data communication. FWB works intensively on the development of cost-efficient system components for POF networks. In cooperation with the University of Applied Sciences Harz, we have developed our first product for the POF technology. The splice facilitates the simple connection of polymer optical fibres using an adhesive that hardens under UV light.

This system enables the simple, quick and clean connection of the single fibres with an extemely small loss in performance. Furthermore, we are developing a splitter to split one fibre into two (Y). It is our goal to produce a cost-efficient and very small system component which will set new standards in this sector.

German

German English

English